What is resin transfer moulding?

Resin transfer moulding (RTM) is a manufacturing process that combines the advantages of injection moulding and layup techniques. RTM can be used to produce composite parts with high accuracy and repeatability, and it is capable of producing parts with complex geometries.

Resin transfer moulding (RTM) is a manufacturing process that combines the advantages of injection moulding and layup techniques. RTM can be used to produce composite parts with high accuracy and repeatability, and it is capable of producing parts with complex geometries.

Advantages of resin transfer moulding

RTM offers several advantages over traditional

composite manufacturing processes, such as hand layup and vacuum infusion. First, RTM produces parts with much tighter dimensional tolerances than other processes. This is due to the fact that the injection of resin into the mould under pressure ensures an even distribution of material throughout the part. Also, because there are no overflows of resin or fibreglass, like when using the hand layup procedure, there is a lesser amount of waste from this process.

This is an efficient method for achieving a higher volume of products rather than employing the time-honoured hand layup process.

Disadvantages of resin transfer moulding

One of the main disadvantages of using

resin transfer moulding is that it can be quite expensive. This is because the process requires specialised equipment and materials, which can drive up the cost. Additionally, resin transfer moulding can be quite time-consuming, which can also add to the overall cost.

Another potential downside to using resin transfer moulding is that it can be difficult to control the final shape and size of the product. This is because the liquid resin needs to be evenly distributed throughout the mould in order to avoid any defects. If there are any imperfections in the mould or in the distribution of the resin, it can result in an uneven or defective final product.

Steps in resin transfer moulding

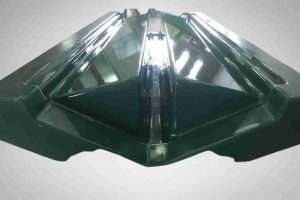

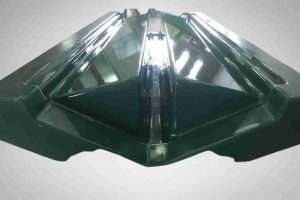

The process begins with the placement of reinforcement fibres (fibreglass) into a mould. The mould is then closed and injected with resin under pressure. The resin saturates the reinforcement fibres, bonding them together to create the desired shape. It also flows into any voids in the mould, creating a strong and even product. After a suitable curing time, the mould is opened, and the part is removed. The process ends with trimming any excess resin away from around the composite part.

Materials used in resin transfer moulding

The most common type of resin used in resin transfer moulding is

epoxy resin. This type of resin is known for its strength and durability, making it ideal for use in applications where parts need to be able to withstand high temperatures or heavy loads. Other types of resins that are sometimes used in resin transfer moulding include

polyester resins and vinyl ester resins.

In order to create parts using resin transfer moulding, a

mould must first be created. The mould can be made from a variety of materials, but the most common material used is fibreglass or metal or combination.

Why use RTM?

RTM is a manufacturing process that can be used to produce

composite parts with high dimensional accuracy and repeatability. RTM is well suited for the production of small to medium-sized parts with complex shapes. The process is capable of producing parts with very tight tolerances and smooth surface finishes.

Resin transfer moulding (RTM) is a manufacturing process that combines the advantages of injection moulding and layup techniques. RTM can be used to produce composite parts with high accuracy and repeatability, and it is capable of producing parts with complex geometries.

Resin transfer moulding (RTM) is a manufacturing process that combines the advantages of injection moulding and layup techniques. RTM can be used to produce composite parts with high accuracy and repeatability, and it is capable of producing parts with complex geometries.