Are composite products a good fit for my business?

Are you a business owner looking for a new way to get your product to market faster? Are you considering incorporating composite products into your manufacturing process but aren’t sure if it’s the right fit? Composite materials offer a range of advantages including strength, lightweight, and cost efficiency. They can also be tailored to meet specific needs and application requirements. By incorporating composite products into your manufacturing process, you can reduce production time and costs while improving product quality. Additionally, composite materials are recyclable and environmentally friendly which can help boost customer loyalty.In order to make sure that composite materials are the right fit for your business, it is important to evaluate all of the potential benefits and drawbacks as well as any associated risks. It is also important to consider the unique needs of your product or application in order to select the most appropriate material. A qualified supplier or consultant can provide valuable advice on selecting the right material for your specific application.

Are you a business owner looking for a new way to get your product to market faster? Are you considering incorporating composite products into your manufacturing process but aren’t sure if it’s the right fit? Composite materials offer a range of advantages including strength, lightweight, and cost efficiency. They can also be tailored to meet specific needs and application requirements. By incorporating composite products into your manufacturing process, you can reduce production time and costs while improving product quality. Additionally, composite materials are recyclable and environmentally friendly which can help boost customer loyalty.In order to make sure that composite materials are the right fit for your business, it is important to evaluate all of the potential benefits and drawbacks as well as any associated risks. It is also important to consider the unique needs of your product or application in order to select the most appropriate material. A qualified supplier or consultant can provide valuable advice on selecting the right material for your specific application.

Introducing Composite Products

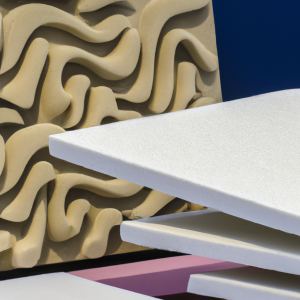

Composite products are combinations of materials that merge to form a single product with its own unique properties. Composite products are created by combining two or more distinct materials, such as fibres and resins, to create a new material with properties superior to those of the constituents. Composite materials are used in a wide range of industries and applications, including aerospace, automotive, construction, sporting goods and electronics. Common examples of composite materials include carbon fibre-reinforced plastic (CFRP), fibreglass-reinforced plastic (FRP), Kevlar-reinforced nylon and wood-plastic composites (WPC).

Benefits of Using Composite Products

Using composite products can offer a range of benefits for both consumers and businesses. Composite products are strong, durable and lightweight, making them ideal for a variety of applications. They are also more resistant to corrosion and wear than other materials, further increasing their longevity. Composite products can be customized easily in terms of size, shape and colour, allowing them to be tailored to meet individual needs. Additionally, they are often cheaper than traditional materials such as steel or aluminium and require less maintenance due to their resistance to weathering and damage. Finally, composite products are environmentally friendly as they require fewer resources in production and generate less waste during their lifespan than other materials. All these benefits make composite products an attractive option when considering the material used for any project or product development.

What Are Your Business Goals?

When considering composite materials for your business, it’s important to think about your business goals. Are you looking for a material that can stand up to wear and tear, be cost-effective, and increase efficiency? Do you need a material that is lightweight yet strong? Or are you looking for something with a unique finish or texture? Whatever your goals, there are composites that can help you achieve them. Many composites offer excellent strength-to-weight ratios, durability and wear resistance, cost savings, and design flexibility. For example, our products are made from composite materials that offer high profitability and independence as a company.

Weigh the Cost of Materials vs Efficiency

When it comes to composite products, one of the most important factors to consider is the cost of materials versus efficiency. It’s important to understand the costs associated with composite materials versus other options, as well as the potential benefits of using them. Composite materials usually cost more than wood, but they can offer greater efficiency in terms of insulation and strength. Additionally, when it comes to shipping and handling costs, composite products are often more cost-efficient because they have a greater capacity and can easily double stack.

Ultimately, it’s important to weigh the cost of the materials against their efficiency benefits when deciding whether composite products are a good fit for your business. Consider your budget and business goals and determine if the added cost is worth the efficiency benefits that come with using composite products.

How Will You Overcome Limitations?

Using composite materials for product development can present its own unique set of challenges. Additionally, composite materials require more precision to ensure a quality product.

To ensure a successful product, it’s important to have an experienced team with deep knowledge of composite materials. Researching the different types of composites available, as well as the process and techniques used to create products with these materials, can help you find the right fit for your business. It’s also important to consider the lead times and costs associated with producing composite parts, as well as any potential quality control or testing that may need to be done.

Managing Lead Times and Costs for Composite Parts

When considering composite materials, it is important to consider lead times and costs associated with these components. Depending on the complexity of the part design, the raw material and the production process, lead times can range from weeks to months. Additionally, the costs associated with these materials can vary depending on the supply chain configuration, tax rates for business and non-business use, and VAT rates. It is important to work closely with your supplier to understand any additional costs associated with composite parts. Additionally, 3D printing and CNC machines have become a great way to reduce lead times and cost of production for complex parts and automotive industries have long been pioneers in the use of composite materials.

Consider Design Flexibility with Composites

When it comes to design flexibility, composite products are a great option. They are lightweight, durable, and easy to work with compared to other materials. This makes them an attractive option for many businesses looking to reduce costs while simultaneously improving the performance of their products.

Quality Control and Testing for Composite Components

When it comes to quality control and testing for composite components, there are several factors to consider. Composite materials can be difficult to inspect due to their complex nature. It is important to ensure that the materials are up to the required standards, as well as to determine the fitness for the use of the remaining parts after testing. Leveraging years of experience producing moulds and composite enclosures, many businesses use bend tests or identity tests on a pooled sample to inspect the material. It is essential to invest in quality control and testing for composite components to ensure the safety and longevity of your product.

Swift Composites team has vast experience designing, developing and making composite products to the highest standard for our customers. If you would like to find out more use the button below to contact us.